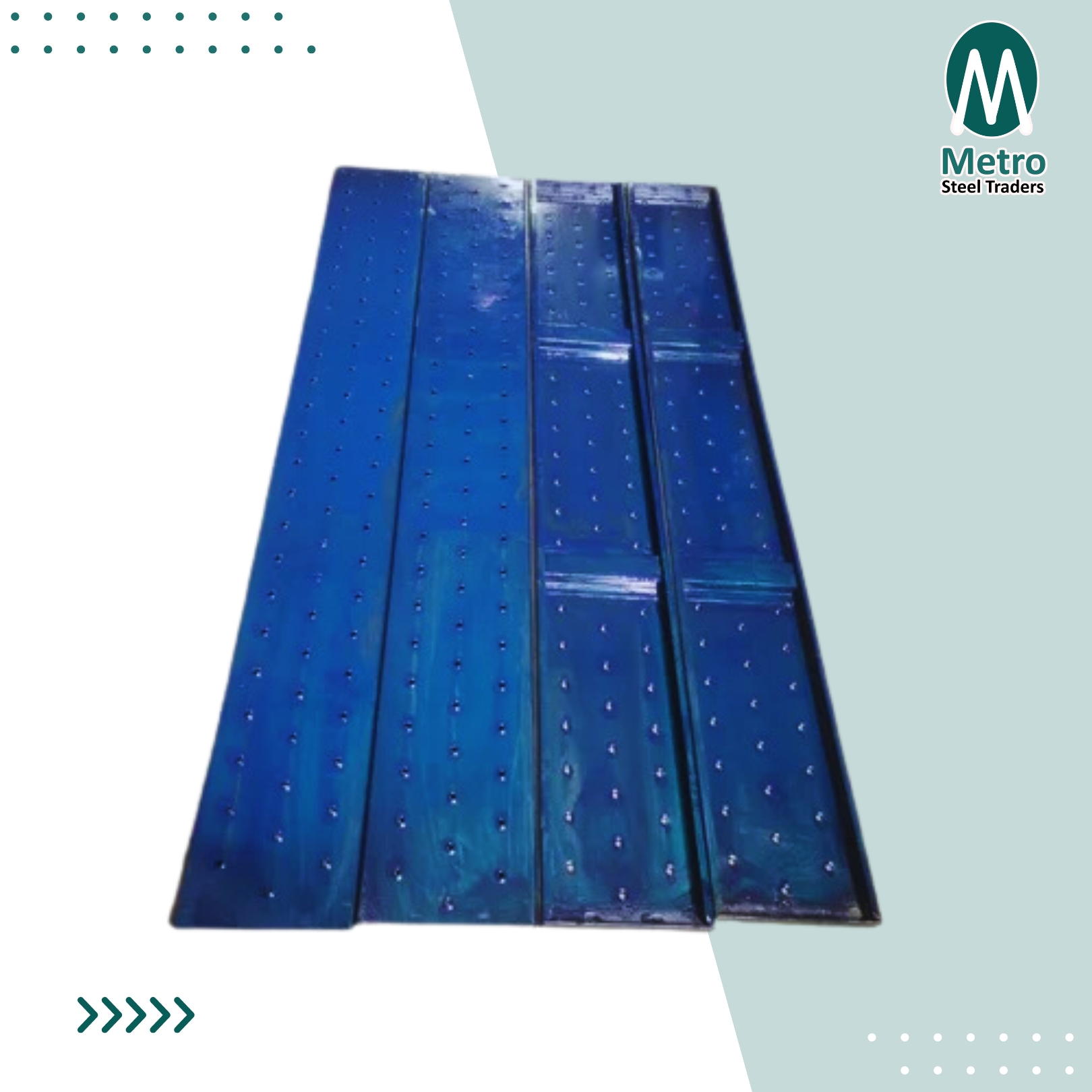

Walkway Planks

Introduction to Walkway Planks

Walkway planks have emerged as an indispensable solution for ensuring safe and efficient passage across construction sites. These planks, designed with precision engineering, serve as a robust and reliable means to traverse uneven terrains and hazardous areas, thus mitigating the risks associated with construction environments. The inherent importance of such safety measures cannot be overstated, as they play a crucial role in preventing accidents and injuries among workers.

In the dynamic and often unpredictable setting of a construction site, the need for durable and stable pathways is paramount. Walkway planks address this necessity by providing a consistent and secure surface for movement. Their construction is tailored to withstand the heavy-duty demands of construction activities, ensuring longevity and resilience under continuous use. This durability is a defining feature, setting walkway planks apart as a preferred choice for site managers aiming to enhance safety protocols.

The Importance of Safety on Construction Sites

Safety on construction sites is paramount, not only for the well-being of the workers but also for the overall efficiency and success of the project. Statistics show that construction sites are inherently hazardous, with the U.S. Bureau of Labor Statistics reporting that, in recent years, construction-related accidents have accounted for a significant percentage of workplace injuries. Common hazards include falls, trips, slips, and the mishandling of heavy materials, which can lead to severe injuries or even fatalities.

Given these risks, implementing robust safety measures is essential. One such measure is the use of durable walkway planks. Walkway planks serve as a stable and secure pathway, significantly reducing the risk of falls and trips. They provide a non-slip surface that can withstand heavy foot traffic and the movement of equipment, ensuring that workers can navigate the site safely even in adverse weather conditions.

Features of Precision-Engineered Walkway Planks

Precision-engineered walkway planks are a cornerstone of modern construction site safety, offering an amalgamation of durability, stability, and reliability. These planks are meticulously designed using advanced engineering techniques that ensure they meet stringent safety standards and perform optimally under varying conditions. The precision engineering process involves state-of-the-art manufacturing technologies that guarantee uniformity and consistency in each plank produced. This high level of precision ensures that the planks fit seamlessly together, reducing the risk of gaps or misalignment that could potentially lead to accidents.

The materials used in these walkway planks are selected for their superior strength and resilience. Typically, high-grade metals like aluminum or steel are employed due to their excellent load-bearing capacities and resistance to environmental factors such as corrosion and wear. In some cases, composite materials may also be used, offering a balance of lightweight properties and robust performance. These materials are subjected to rigorous testing to ensure they can withstand the harsh conditions commonly found on construction sites.

Durability and Longevity of Walkway Planks

Walkway planks are engineered to provide a safe and reliable pathway in construction sites, where durability and longevity are paramount. These planks are typically constructed from robust materials such as treated timber, steel, aluminum, or composite materials. Each of these materials offers unique benefits in terms of strength and resistance to wear and tear.

Treated timber planks, for instance, undergo a preservation process that imbues the wood with enhanced resistance to environmental factors such as moisture, insects, and fungi. This treatment extends the lifespan of the planks, making them a viable option in both wet and dry conditions. On the other hand, steel and aluminum planks are renowned for their exceptional strength and load-bearing capacity. These metals are resistant to corrosion, especially when coated with protective layers, ensuring that they remain functional in harsh weather conditions.

Applications in Industrial and Construction Settings

Walkway planks have become a cornerstone in ensuring safe and efficient movement within industrial and construction settings. These durable solutions are designed to withstand heavy loads and harsh environmental conditions, making them indispensable across various sectors. Their implementation ranges from large-scale construction projects to more specialized industrial applications, each benefiting from the structural integrity and safety features that walkway planks provide.

In the construction industry, walkway planks are frequently deployed to create temporary pathways across uneven or hazardous terrain. For instance, on a bustling construction site, these planks can be used to construct stable walkways over muddy or unstable ground, ensuring that workers can move equipment and materials safely and efficiently. This not only enhances operational workflow but also minimizes the risk of accidents, contributing significantly to overall site safety.

Installation and Maintenance of Walkway Planks

The installation of walkway planks on construction sites necessitates adherence to precise guidelines to ensure safety and durability. Begin by assessing the terrain where the walkway planks will be installed. The ground should be leveled and cleared of any debris to provide a stable foundation. Next, measure and mark the designated area to ensure proper alignment of the planks.

Once the area is prepared, place the first plank at the starting point and secure it firmly using appropriate fasteners. It is crucial to ensure that each plank is flush with the ground and adjacent planks to prevent tripping hazards. Continue placing subsequent planks, maintaining consistent spacing and alignment. For elevated walkways, support structures such as braces or scaffolds should be utilized to enhance stability.

When fastening the planks, use corrosion-resistant screws or bolts to withstand environmental elements. Additionally, ensure that the fasteners are countersunk to avoid protruding edges. For added safety, consider incorporating non-slip surfaces or coatings on the planks, especially in areas prone to moisture.

Comparing Walkway Planks to Alternative Solutions

In the realm of construction site management, ensuring safe and efficient passage is paramount. Various solutions have been employed over the years, each with its own set of advantages and disadvantages. Among these, walkway planks have consistently emerged as a preferred option. To understand why, it is essential to compare them to other common alternatives such as gravel paths, temporary mats, and metal walkways.

Gravel paths are a traditional choice due to their simplicity and low cost. However, they come with significant drawbacks. Gravel can easily become uneven and may pose tripping hazards, especially in wet conditions. Moreover, maintaining gravel paths requires frequent leveling and replenishment, adding to long-term costs and labor efforts. Walkway planks, in contrast, provide a stable and even surface, reducing the risk of accidents and minimizing maintenance needs.

Conclusion: Enhancing Safety and Efficiency with Walkway Planks

In the realm of construction site management, ensuring the safety and efficiency of operations is paramount. Walkway planks play a crucial role in this regard, offering a durable and reliable solution for safe passage across uneven and potentially hazardous terrains. The benefits of utilizing walkway planks extend beyond mere convenience; they are integral to maintaining a safe working environment, which can significantly reduce the risk of accidents and injuries.

Walkway planks are designed with durability in mind, often constructed from robust materials that can withstand the harsh conditions typical of construction sites. This durability ensures a long service life, making them a cost-effective investment for construction companies. Moreover, the safety features inherent in walkway planks, such as non-slip surfaces and load-bearing capabilities, contribute to a safer workspace, allowing workers to move confidently and securely.

Our Office: Metro Steel Traders

Phone: (+91 ) 98250 21873

Mail: info@metrosteeltraders.com